Bearing package qualification for indestructible encoders

The ultimate endurance test for encoder ball bearing packages

Simulation of environmental conditions prevents machine downtimes

As a manufacturer of incremental and absolute encoders that operate reliably worldwide and in many different applications, Wachendorff Automation attaches great importance to the validation of individual components during the development process.

Since we do not always know the applications our encoders and measuring systems are used within, we carry out as many environmental simulations as possible. This gives us the certainty that our encoders will run precisely and reliably for many years, even in the most demanding of applications & enviroments.

For each new product family, there is a comprehensive verification and validation strategy that starts with the suppliers and the components. Assemblies and finished products are subjected to long-term tests which cover the wide range of applications for our encoders & systems. We do not rely soley on the information provided by our suppliers, but carry out extensive additional tests in our own test laboratories, including Temperature fluctuations and temperature resistance up and down in the HALT chamber, vibration and shock resistance in special shakers along with tests to confirm the IP protection class & EMC.

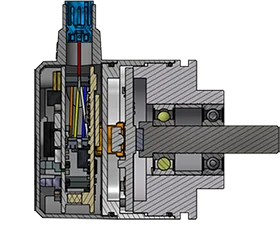

A core component of the encoder and the focus for many of these tests and qualifications, are the ball bearings and the associated bearing package. The dimensioning as well as the qualification of these components are decisive for the quality and longevity of an encoder and are therefore regarded as one of our core competences.

If, like Wachendorff, you provide a 5-year guarantee on your encoders, it is not enough to soley rely on information from suppliers and mathematical calculations alone. It is not without justification that Wachendorff proclaims that it offers the most robust encoders that can withstand the highest radial and axial bearing loads and are therefore well suited for use in applications that require the highest demands.

Anyone who has ever been involved in the selection and qualification of ball bearing packages knows that after you have approved the right manufacturer, you only get quite trivial information regarding durability. Every high quality manufacturer delivers a corresponding quality in which the customer can only intervene to a limited extent. Only after an examination of the process safety, quality assurance and final testing, do you receive a quality product, which can now be designed in.

There are a standardised formulae, particularly in DIN ISO 281, in which the service life and theoretical bearing loads can be calculated which have been tried and tested for decades and are still only conditionally reliable. There are some parameters that are only taken into account to a limited extent in the calculations, but in reality play a major role, e.g. temperature fluctuations, dynamic loads, tolerances in assembly, to name but a few.

When developing our series of absolute encoders with Industrial Ethernet interfaces such as PROFINET and EtherCat, the challenge was to develop the most compact encoder in the world for this purpose, which, despite its compactness, can "bear" sufficient bearing loads to ensure many years of trouble-free operation in the field in industrial applications and, for example, in mobile machinery.

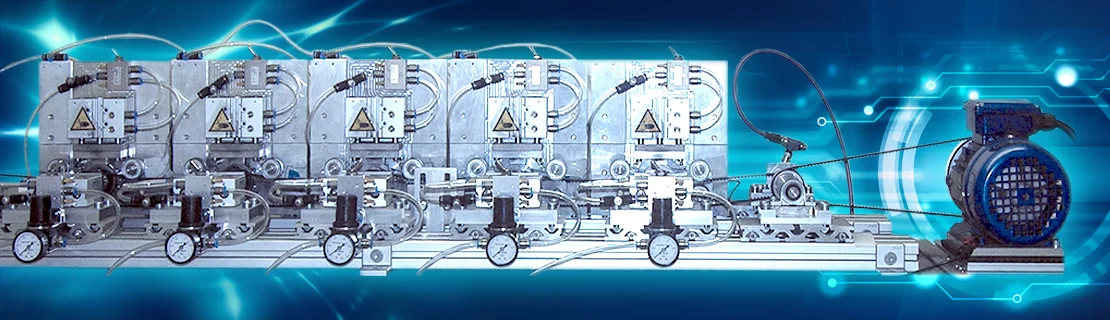

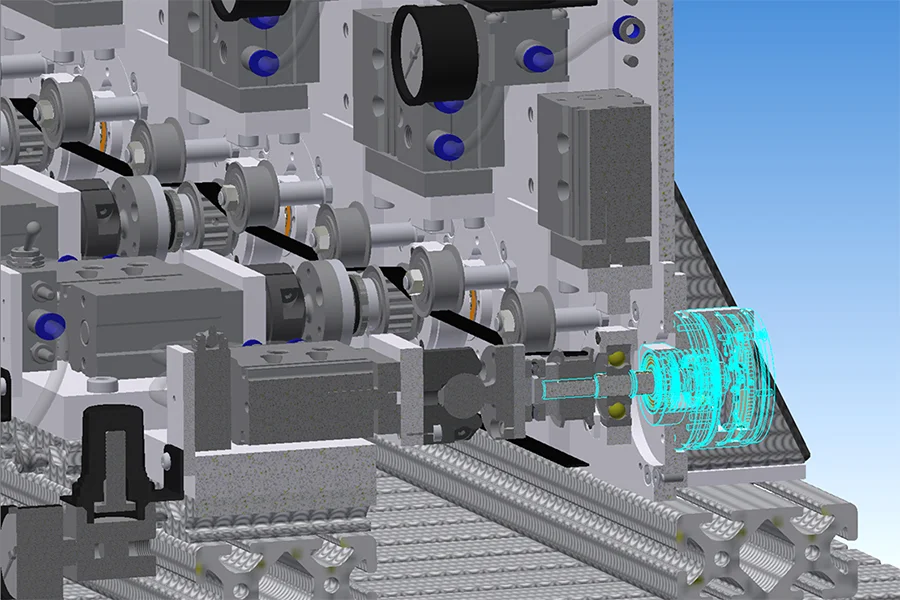

For this purpose, the existing bearing package test station was supplemented and automated so that the calculated service life of the bearing packs mounted (glued) in the flange of our encoders can be verified. The test station is completely enclosed so that the noise generated during the test process is muffled and employees are not endangered in the event of a defect.

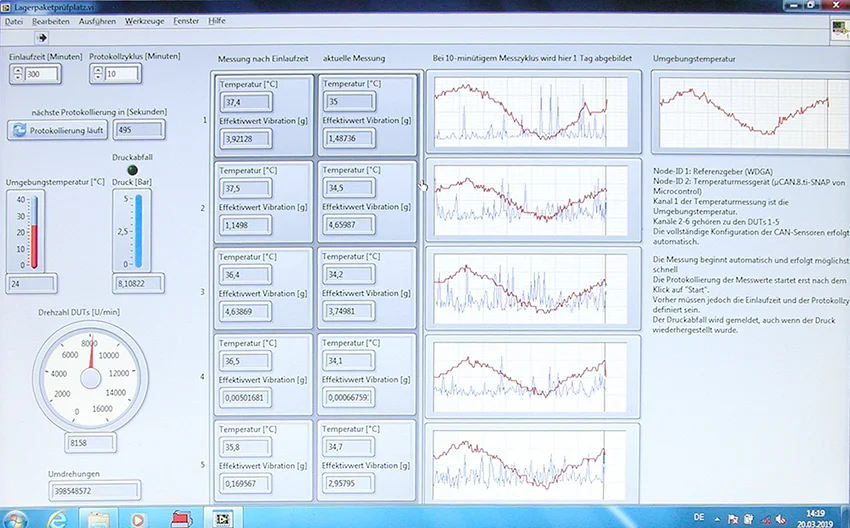

In this example, the bearings are subjected to the maximum permissible loads - the encoder WDAG58F with axial 50 N, radial 60 N - at the maximum speed of 8000 rpm.

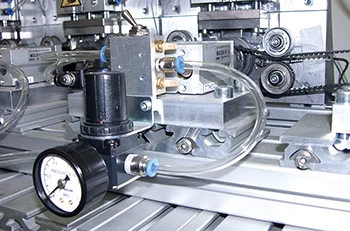

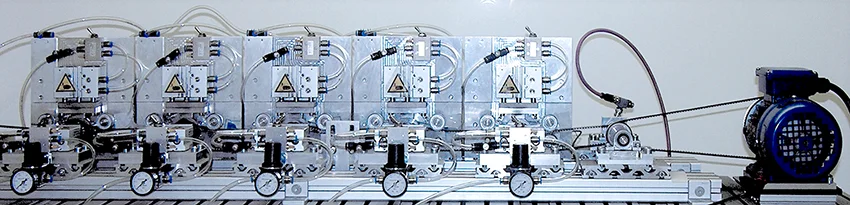

The loads are applied to the test piece shafts by pneumatic cylinders. Each pneumatic cylinder is controlled or adjusted by a separate pressure regulator. The force resulting from the set pressure is verified during commissioning with a pressure force sensor.

The ball bearing package test rig basically offers the possibility to apply both radial and axial loads to the test shaft at the same time. The radial force is the decisive factor for the service life calculation. In the calculation, the axial load is only taken into account from a certain ratio to the radial force, otherwise it is assumed to be "0". This condition applies in our example and reduces the test to a purely radial load.

5 test items can be verified simultaneously. On the one hand, this gives a statistically higher probability of detecting a defect and thus a more stable statement in the test result and on the other hand, it allows comparative tests to be performed.

The test specimens are driven by an electric motor, which generates the desired speed by means of a transmission and a toothed belt system with the speed and the number of revolutions being measured by an encoder.

The temperature and vibration of each test specimen are permanently measured directly at the bearing package.

The application provides a display of the currently recorded measured values (temperature, speed, vibration, load, number of revolutions) along with a history of the measured values over the last 24 hours. A reference measurement from the start of the test run is also displayed and thereby any changes in the measured values can also be easily detected.

In addition to the display, all measured values are written to a file, which enables evaluation and analysis in e.g. Excel or other programs.

Depending on the selected speed and the calculated service life at 100% assumed bearing load, the verification of a bearing package takes approx. 12 to 15 weeks.

In our example for the Industrial Ethernet encoder, the test items successfully passed the test after 13 weeks - an extremely reassuring feeling to receive objective confirmation that you have made the right choice!